Real-World Results. Real-World Impact.

Turning Engineering Insight into Scalable Impact.

Over the past 17+ years, I've led engineering projects from concept to commissioning; delivering technical clarity, operational efficiency, and AI-readiness at scale. Below is a selection of work where strategy meets execution.

* Selected projects. Not in chronological order.

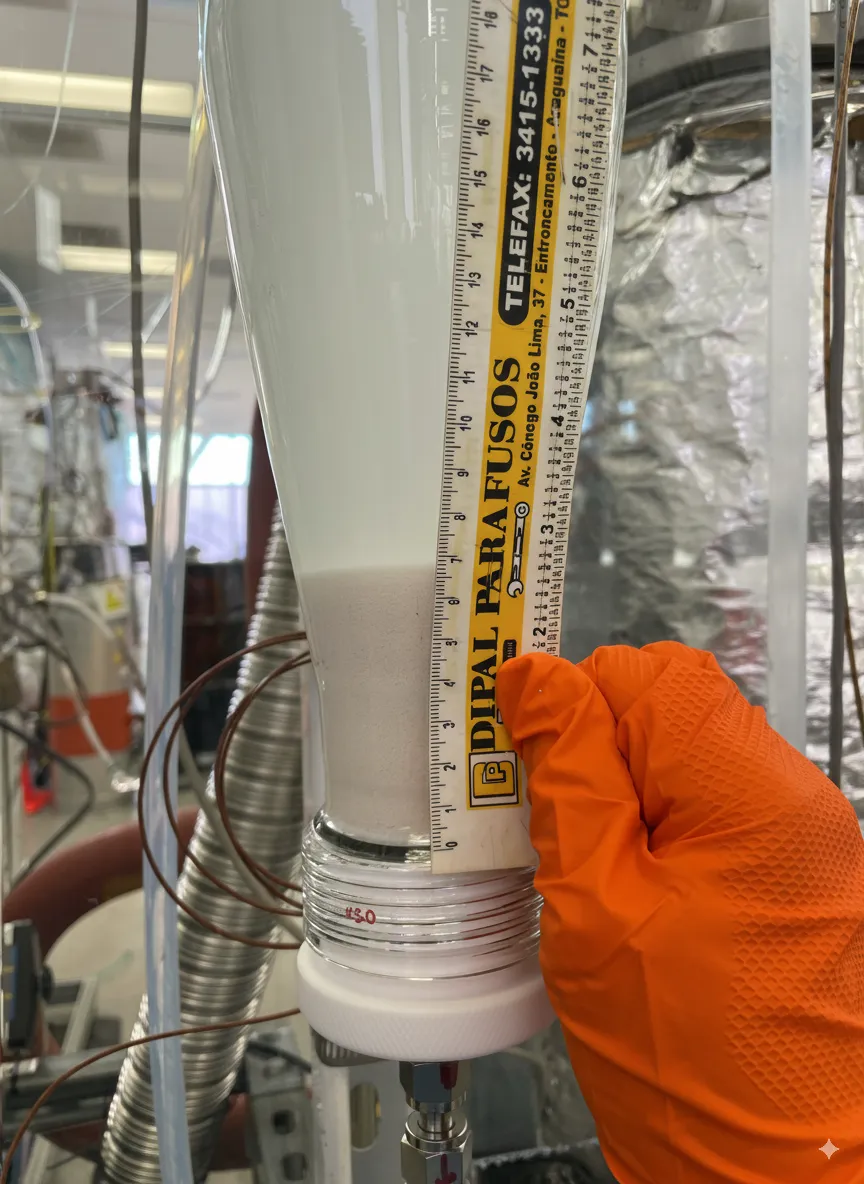

🧪 Nanoparticle Filtration System

⚙️ Company: Halio Inc. | Role: Senior Mechanical Engineer

📍 Location: Hayward, CA

🔍 The Challenge:

Production of sulfolane, a key chemical in Halio’s electrochromic glass, was being contaminated by pink nanoparticles. The existing manual filtration process required halting production for days and demanded constant labor, threatening both product purity and operational efficiency.

🛠 My Solution:

Identified root cause through hands-on research and process analysis

Developed and tested a fluidized bed filtration reactor at lab scale

Scaled the design, calculated system requirements, and engineered full inline deployment

Led a cross-functional team (automation, electrical, chemical, mechanical) for installation and commissioning

Integrated the system inline—eliminating manual steps and production downtime

🏆 Outcome:

Improved production by 400%, restoring color consistency in final products

Improved product purity from 96% to 99.98%.

Reduced labor hours dramatically with a fully automated inline system

Eliminated multi-day production halts and improved plant throughput

Delivered a low-maintenance solution fully compliant with safety standards

🧠 What I Learned:

By combining scientific method, proof of concept, and systems thinking, complex problems become solvable. Collaboration and structured feedback loops are the fastest way to innovation and operational excellence.

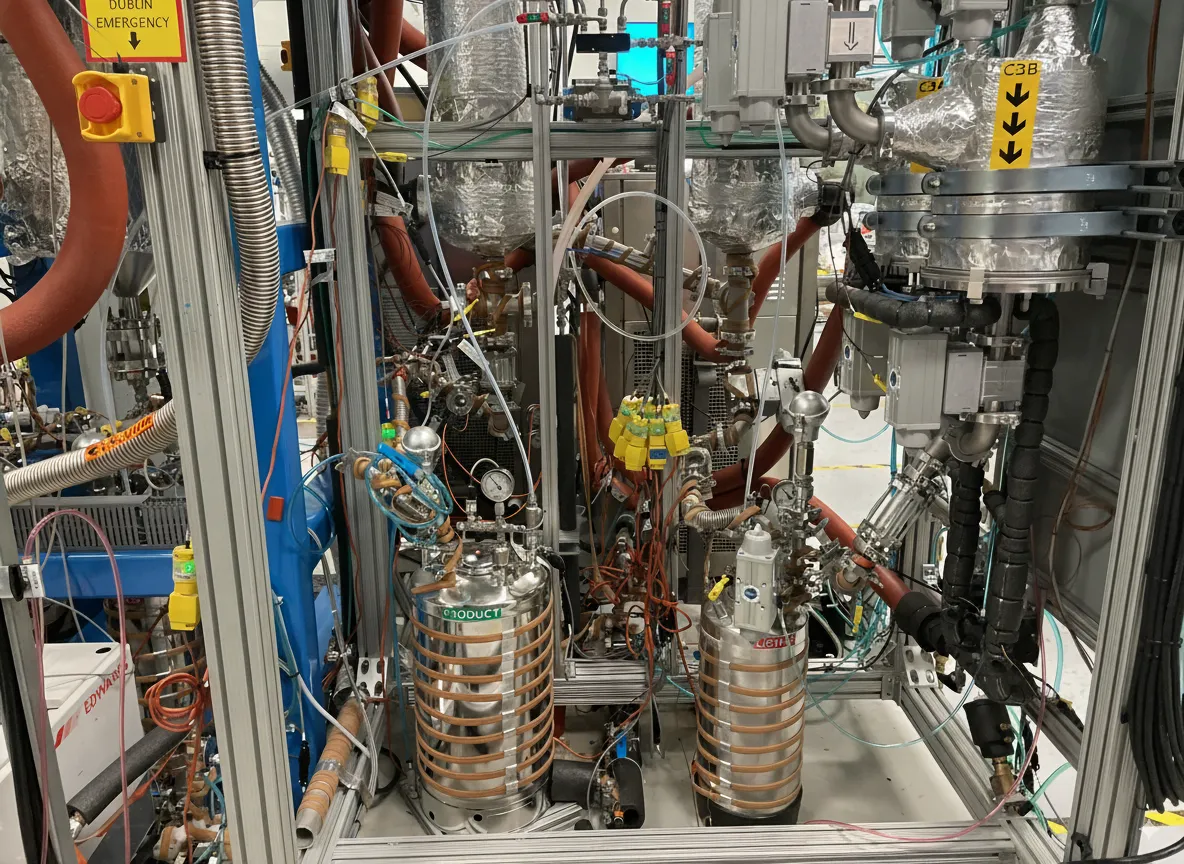

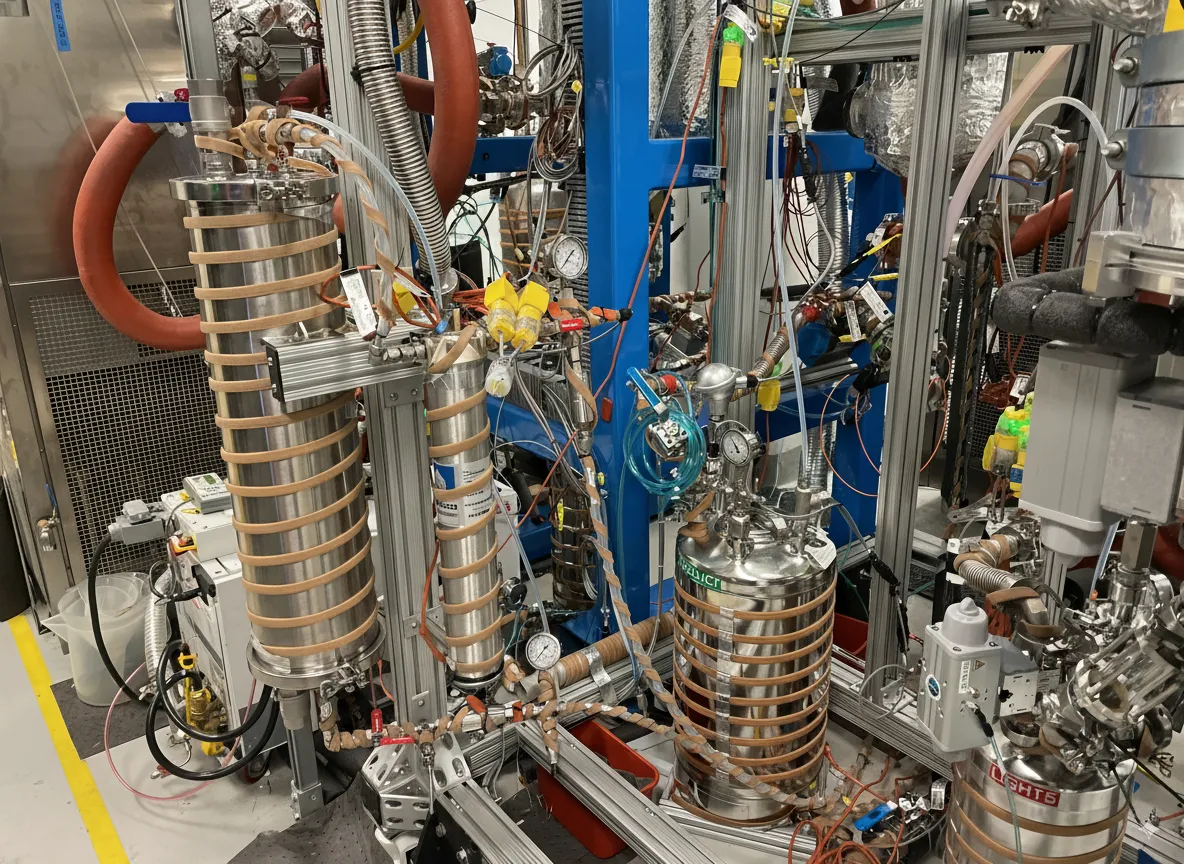

🔋 Ion Plant Scale-up

⚙️ Company: Halio Inc. | Role: Senior Mechanical Engineer

📍 Location: Hayward, CA

🔍 The Challenge:

Halio needed to scale its ion production from 20 kg to over 300 kg per week—a 1,400% increase in output. The existing system was largely manual, relying on oversized glass reactors with no automation or standard controls. Scaling under those conditions posed serious risks to safety, consistency, and throughput.

🛠 My Solution:

Mapped the entire legacy production workflow to identify bottlenecks and inefficiencies

Created process flow diagrams and detailed P&IDs (Piping and Instrumentation Diagrams)

Collaborated with in-house scientists to refine and modernize the process design

Engineered a new system using stainless steel equipment, compliant with safety and cleanability standards

Led the integration of automation controls, sensors, and safety interlocks across all process stages

🏆 Outcome:

Scaled production from 20 kg to 300+ kg per week — a 1,400% increase in capacity

Replaced all manual operations with an automated, safe, and consistent system

Reduced production errors and improved system traceability and quality control

Delivered a plant-ready system that’s now a core part of Halio’s high-throughput manufacturing

🧠 What I Learned:

Scaling isn’t just about equipment—it’s about clarity and communication. Working across scientific, engineering, and automation teams taught me that process mapping and systems alignment are essential for building reliable, scalable infrastructure.

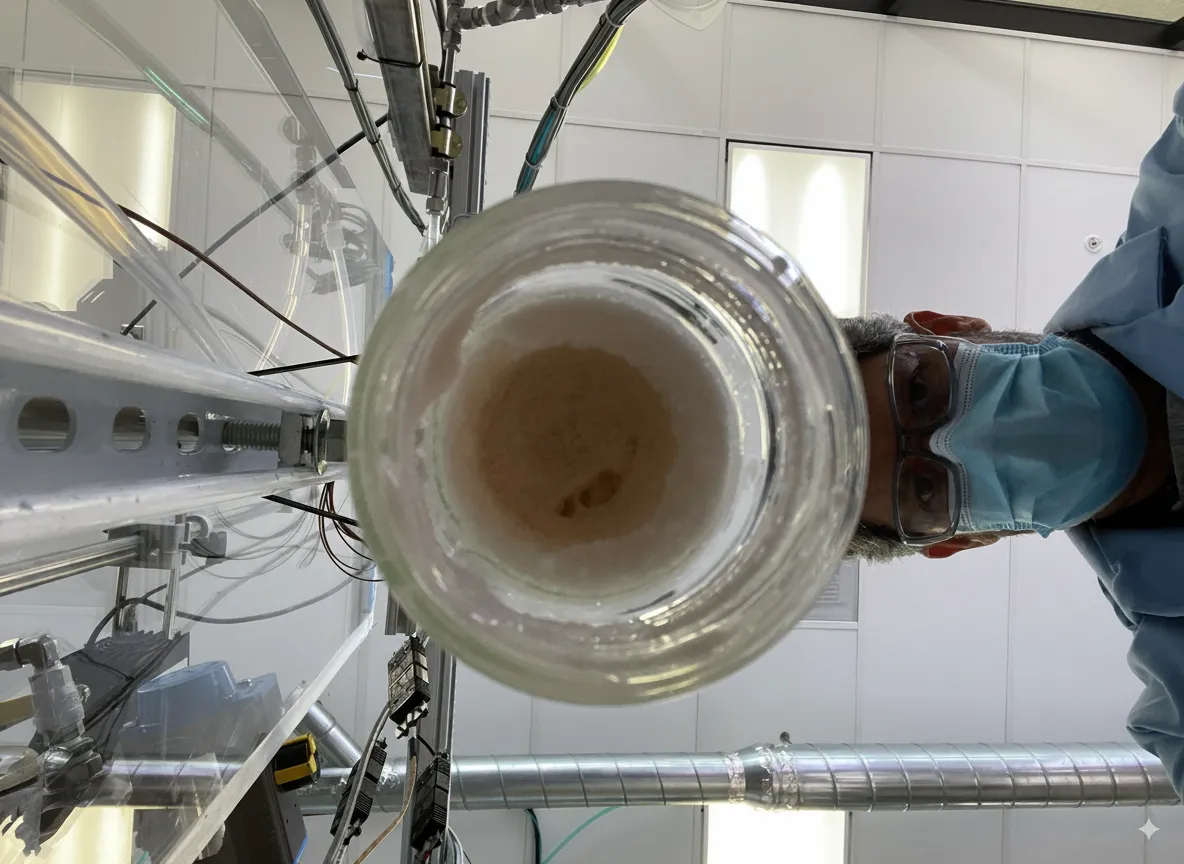

🧪 Sulfolane Rectification Column

⚙️ Company: Halio Inc. | Role: Senior Mechanical Engineer

📍 Location: Hayward, CA

🔍 The Challenge:

Halio’s distillation system was operating at low efficiency, later pushed to higher through internal tweaks—but that still wasn’t enough. To raise purification levels further, a rectification column was proposed. However, this system ran under low pressure and narrow thermal margins: temperatures too high caused fluid degradation; too low led to gel formation. Complicating matters, the physical space available for installation was extremely limited, and the production line couldn’t be interrupted.

🛠 My Solution:

Developed a custom simulation tool to calculate ideal pressure-temperature operating ranges

Designed a full 3D model of the rectification column tailored to tight spatial constraints

Planned a phased installation to avoid production downtime

Oversaw fabrication, installation, and system commissioning

Led incremental system optimizations post-deployment for maximum performance

🏆 Outcome:

Boosted purification efficiency to 96%, a key milestone for product quality

Achieved this without pausing plant operations or risking product degradation

Delivered long-term savings through reduced reprocessing and increased yield stability

🧠 What I Learned:

New domains may be unfamiliar, but the engineering method remains constant. Through rigorous research, simulation, and structured iteration, even the most constrained challenges can be turned into powerful wins.

🔋Biomass Gasification Power Plant

⚙️ Company: Gaslin | Role: Plant Engineer

📍 Location: Linhares, Brazil

🔍 The Challenge:

Gaslin was building the first 1 MW thermal biomass gasification pilot plant in South America—a pioneering project with no prior roadmap. As Plant Engineer, I was tasked with turning complex engineering designs into operational reality. With an entirely new system and limited precedent, execution demanded both technical depth and human leadership.

🛠 My Solution:

Took full ownership of daily plant operations and engineering execution

Coordinated all technical projects, translating designs into on-site implementation

Built strong relationships with cross-functional teams, creating a unified project culture

Applied mechanical engineering knowledge across piping, layout, installation, and process tuning

Learned directly from senior engineers to accelerate execution and avoid design pitfalls

🏆 Outcome:

Delivered Brazil’s first circulating fluidized bed biomass gasification system

Proved the concept’s viability at a 1 MW scale, setting the foundation for future commercial plants

Gained hands-on mastery over multidisciplinary field engineering in a high-stakes environment

🧠 What I Learned:

This project marked a turning point in my career. I learned that execution is as much about people as it is about engineering. When teams align around purpose and process, even groundbreaking systems can be built from the ground up—literally.

🧪 Waste-to-Energy Power Plant

⚙️ Company: Pneuvix | Role: Mechanical Engineer

📍 Location: Vitoria, Brazil

🔍 The Challenge:

Pneuvix set out to build a closed-loop energy system that would convert waste tires into fuel and power. The challenge was to design a fully integrated operation: shredding tires into robber chips, gasifying them in a a Bubbling Reactor, and using the resulting fuel gas to power a steam turbine — all while feeding energy back into the shredding system and selling surplus power to the grid.

🛠 My Solution:

Supported system design by conducting mass and energy balances across the entire process

Co-authored the technical specification package for procurement and fabrication

Created detailed process flow diagrams and system schematics

Worked alongside the engineering team to ensure operational feasibility and system integration

🏆 Outcome:

Successfully delivered a functioning waste-to-energy power plant, now operational in Vitória, Brazil

Enabled energy self-sufficiency within the shredding system and revenue from power export

Contributed to an innovative model for circular economy in industrial waste management

🧠 What I Learned:

This project proved that systems thinking is a universal problem-solving tool. Whether it’s energy, engineering, or life itself — when you understand the parts and the relationships, you can design the whole with purpose and efficiency.

🔋Elevator Installation Project Management

⚙️ Company: Thyssenkrupp | Role: Project Manager

📍 Location: King of Prussia, PA

🔍 The Challenge:

At Thyssenkrupp, I was tasked with managing 16+ simultaneous elevator installation and site preparedness projects, all in different phases, sizes, and locations. The complexity of timelines, contractor coordination, and stakeholder expectations made traditional tracking methods unworkable.

🛠 My Solution:

Built a custom project management system to centralize task tracking, scheduling, and reporting

Developed a personal knowledge management (PKM) framework to capture key data across projects

Created automated workflows and reminder systems to avoid delays and missed dependencies

Standardized processes across projects to drive consistency and reduce cognitive load

🏆 Outcome:

Successfully managed 30+ major elevator installation projects without delays or overruns

Streamlined communication with cross-functional teams and contractors

Increased overall visibility and control over high-volume, high-stakes projects

🧠 What I Learned:

Process beats pressure. Systems and knowledge management are not optional when leading multiple complex projects. Communication, documentation, and automation were my foundation for sustained performance.

🧪 Conveying System

⚙️ Company: Heat and Control | Role: Project Engineer

📍 Location: Hayward, CA

🔍 The Challenge:

A major food production plant needed to scale up output — but its existing facility was already packed with equipment. Designing a new conveying system in such a tight space meant working with extremely high precision: even a 2-inch misalignment could cause major equipment clashes and process failures.

🛠 My Solution:

Conducted a full onsite layout survey, capturing hundreds of reference points manually

Designed the complete system layout, ensuring spatial accuracy to within inches

Produced all required technical documentation, including diagrams and fabrication-ready drawings

Coordinated a team of designers and provided technical support across departments

Managed communication with stakeholders to align goals, deadlines, and system specs

🏆 Outcome:

Delivered a fully functional conveying system that fit with millimeter-level precision

Enabled production scale-up without disrupting existing operations

Built cross-team trust through detailed documentation and real-time support

🧠 What I Learned:

Precision starts long before installation. Process discipline, documentation control, and constant communication are what make complex retrofits successful in real-world conditions.

🔋 Batch Fryer System

⚙️ Company: Heat and Control | Role: Project Engineer

📍 Location: Hayward, CA

🔍 The Challenge:

A long-time client was operating a proprietary batch-frying system for potatoes — originally designed by our team, but now entirely outdated and documented only in paper. The goal: modernize the system with full automation while preserving the exact same process and recipe that defined the product’s quality.

🛠 My Solution:

Visited the client’s site to study the operation of the legacy system firsthand

Recovered and analyzed all original paper-based design files and documentation

Led the complete redesign using current tools and automation standards

Coordinated mechanical, electrical, and controls engineers through the modernization process

Ensured new system matched original performance with upgraded reliability and efficiency

🏆 Outcome:

Delivered a fully automated batch fryer system that preserves product quality and increases throughput

Transformed decades-old mechanical logic into a state-of-the-art production line

Improved operational reliability, consistency, and ease of maintenance

🧠 What I Learned:

Legacy systems hold powerful insights. Revisiting paper-based designs reminded me how brilliant early engineers were—and how today’s tools can build on that ingenuity to create smarter, more efficient solutions.

🧪 L75 Project Management Assistance

⚙️ Company: Brazilian Space Agency | Role: Assistant Project Manager (Technologist)

📍 Location: Brasilia, Brazil

🔍 The Challenge:

As the agency developed the L-75 liquid-fueled rocket engine, my role as Assistant Project Manager was to track and report on the entire production chain. The key challenge was to translate highly technical progress into actionable insights for non-technical directors — enabling decision-making without losing engineering nuance.

🛠 My Solution:

Visited and audited all manufacturing and integration sites involved in the L-75 project

Mapped workflows and developed custom KPIs (Key Performance Indicators) to measure progress and risks

Built dashboards that visualized real-time data from the project’s lifecycle

Applied storytelling techniques to bridge the gap between technical teams and executive leadership

Acted as a communication link between engineering teams and agency directors

🏆 Outcome:

Delivered an interactive dashboard system that clarified project health for executive stakeholders

Enabled informed, timely decisions across multiple engineering phases

Strengthened alignment between technical execution and strategic oversight

🧠 What I Learned:

Numbers tell stories—if you know how to listen. Blending KPIs with storytelling creates a shared language between engineers and executives, unlocking better communication, smarter strategy, and faster course correction.

🔋 Biomass Gasification Power System

⚙️ Company: Universidade de Brasilia - UnB | Role: Graduation Student

📍 Location: Veredaozinho, Brazil

🔍 The Challenge:

As part of my capstone project, I was tasked with designing and deploying a 5 kW biomass gasification power system in Veredaozinho, an isolated community deep in the Amazon Jungle with no access to electricity. The entire system had to be planned, built, and tested in Brasília, then transported and installed on-site — all without local infrastructure, grid support, or backup power.

🛠 My Solution:

Designed the full biomass gasification and power generation system from scratch

Assembled and led a multidisciplinary team to support engineering, logistics, and field installation

Coordinated procurement, fabrication, and transport of equipment to the Amazon

Supervised the on-site installation, commissioning, and operational validation

Delivered full technical documentation and training for local sustainability

🏆 Outcome:

Successfully deployed a 5 kW standalone power system, bringing electricity to a previously unpowered community

Enabled critical services like vaccine and medication refrigeration for local healthcare

Proved the viability of low-cost, clean energy systems in extreme remote environments

🧠 What I Learned:

This project is one of the proudest moments of my life. It taught me that engineering is a tool for human progress. With the right systems, teamwork, and mission, even a student-led project can change lives.

Check out my social medias

Transforming business through intelligent AI infrastructure solutions.

2025 Business Growth AI Infrastructure Solutions. All rights reserved.

Privacy Policy

Terms of Service

Cookie Policy